Product Information

Machining Products

High-Level Design Ability Creates Advanced Technologies.

Our functional designing skills accompanied by our unique idea and excellent technologies, and our highly developed processing and machining technologies enable us to enhance the features of carbon and graphite materials to the fullest extent. We will continue to supply reliable products and services under a through quality control in various areas, including basic industry areas of Telecommunications, machinery, metallurgy and such, and advanced industry areas of semiconductor and, aerospace industry and such.

Machining Application Products

Our various types of products will lead the world, and will lead the next generation.

(Image of product in use)

Applications

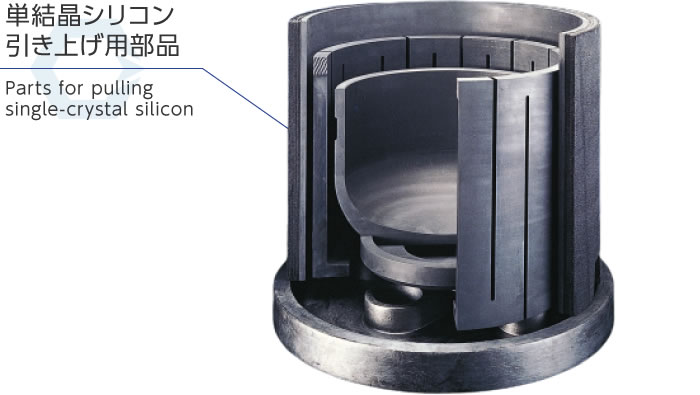

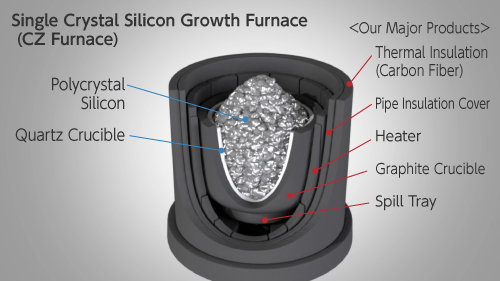

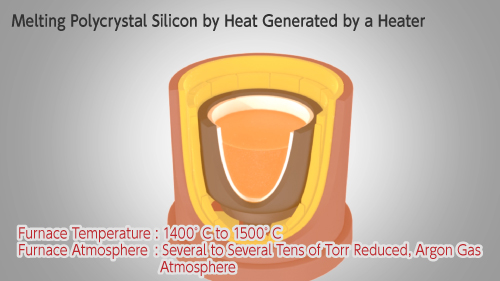

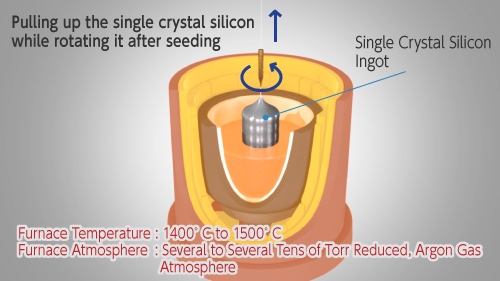

Products for silicon semiconductors, compound semiconductors, solar cells (single-crystal wafers, polycrystalline cells), polysilicon manufacturing, optical fibers, industrial heat treatment, continuous casting, electromagnetic steel sheets, vacuum deposition, aluminum melting, brushes for home appliances , current collector plates, electric discharge machining, chemical electrolysis, and others.

Machining Standard

Dimensional Tolerance

Applicable Standards for Tolerance

Normal tolerances are classified to fine grade, medium grade and coarse grade in JIS B 0405. However, we process isostatic and molding products in compliance with the JIS medium grade while we process extruding products in compliance with the JIS coarse grade (refer to the list below) unless otherwise specified.

Tolerance for Thickness, Width, Length, Internal and External Diameter Example/JIS Intermediate

(mm)

| Classification of Dimensions | Tolerance |

|---|---|

|

Not smaller than 0.5 and not larger than 3 Larger than 3 and not larger than 6 |

±0.1 |

|

Larger than 6 and not larger than 30 Larger than 30 and not larger than 120 Larger than 120 and not larger than 400 |

±0.2 ±0.3 ±0.5 |

|

Larger than 400 and not larger than 1000 Larger than 1000 and not larger than 2000 |

±0.8 ±1.2 |

| Larger than 2000 and not larger than 4000 | ±2.0 |

Normal tolerances are classified to H, K and L grades in JIS B 0419. However, we process CIP and molding products in compliance with the K grade (refer to the list below) while we process extruding products in compliance with the L grade unless otherwise specified.

Tolerance for Shape Example /JIS K

(mm)

| Classification of Dimensions | Tolerance | |

|---|---|---|

| Parallelism and Perpendicularity | Flatness and Straightness | |

|

Not larger than 10 Larger than 10 and not larger than 30 Largar than 30 and not larger than 100 Larger than 100 and not largar than 300 Larger than 300 and not larger than 1000 Larger than 1000 and not larger than 3000 |

0.4 0.4 0.4 0.6 0.8 1.0 |

0.05 0.1 0.2 0.4 0.6 0.8 |

High-Purity Treatment

Our high-purity treatment enables production of carbons with the following grades.

| Grade | Ash(ppm) | Element Content(ppm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | B | Ca | Cr | Cu | Fe | K | Mg | Mn | Na | Ni | Si | Ti | V | ||

| H(KⅡ)Grade | 8 | – | 0.9 | 0.05 | – | – | 0.05 | – | – | – | – | – | 0.2 | – | – |

| SH Grade | 3 | – | 0.7 | – | – | – | – | – | – | – | – | – | – | – | – |

| Analysis method | ICP | ICP | ICP | ICP | ICP | ICP | AAS | ICP | ICP | AAS | AAS | ICP | ICP | ICP | |

- ー: Not Detected

- ICP: Induced Coupling Plasma Atomic Emission Spectroscopy

- AAS: Atomic Absorption Spectrometry

- Values for ash and each element are not guaranteed values but reference values.

- Examples for Each Grade: High Grade = IGS-743H, IGS-603KI, Super High Grade = IGS-743SH.

- Method of Measurement: Complying with JIS R7223.

Special Treatment

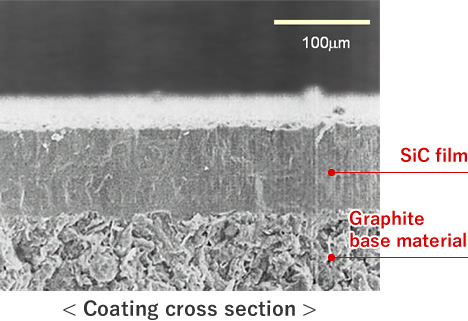

CVD-SiC Coating

The CVD-SIC coating graphite is mainly used for high-temperature processing applications in the semiconductor field since it is highly pure and thermally stable. Our CVD-SiC can be used stably for a long period since it has a crystal quality with strong adhesion to the base material and excellent durability.

- Features of our SiC Coating

-

- It is excellent in adhesion and durability because it is based on a special graphite material.

- Coating of a thick film is available depending on use conditions.

Oxidation Resistance Treatment

Although graphite is highly resistant to heat in an inert atmosphere, it is exhausted by oxidation when used in an oxidizing atmosphere for a long period at temperatures higher than 500℃. Our company performs an oxidation resistance treatment in order to slow down the speed of wear.

- Safety Cautions 《Follow the descriptions below for a safe use of graphite materials.》

-

- Be careful of burn injuries and electrical shocks, because graphite materials are good conductors of heat and electricity. Take measures against powder dust in order to prevent leakage and short-circuit troubles due to powder dust or chips of graphite materials.

- In case powder dust or chips of graphite materials get into your eyes, please wash your eyes immediately. If the powder dust or chips cannot be removed, receive medical treatment. If any dust or chip is stuck to your skin, please wash them away by using water with or without soap.

- Graphite materials are slippery. In cases where the graphite materials are stuck on the floor, please sweep the floor to prevent people from falling down.

- Raw materials are as slippery as final products. Your fingers can be jammed in them or they may drop on your foot. To prevent this, wear gloves and safety shoes when handling graphite materials.

- Since graphite materials are brittle, mechanical shocks can break graphite materials triggering fragments of the graphite materials to fly or drop, which may result in injuries to you.

- Wetting by water or oil can decrease the performance of the materials.

- Have an authorized waste-disposal company dispose used products as industrial wastes when you will be disposing them.