Product Information

Material Products

An Extensive Lineup of Material Blocks Meeting Diverse Needs

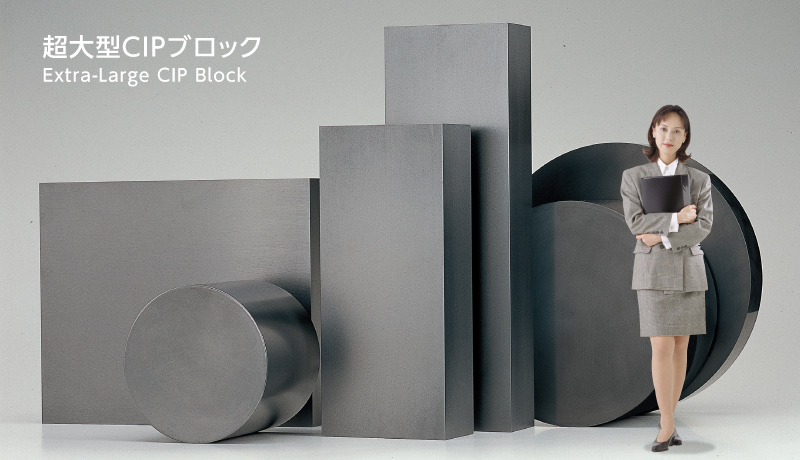

By leading-edge technologies in manufacturing graphite block and excellent technologies in processing and treatment of graphite materials, we will continue to supply reliable products to meet demands of our customers. By taking advantage of our original technologies in manufacturing graphite block, kneading, forming, baking and graphitizing process, we have supplied various grade and size for Ultra-High-Density Products, High-Density Products, and General Purpose Carbon Products. With our long-accumulated specific technologies and know-how , very large size graphite blocks (larger than 1-meter diameter) are available to the most advanced area of industries.

-

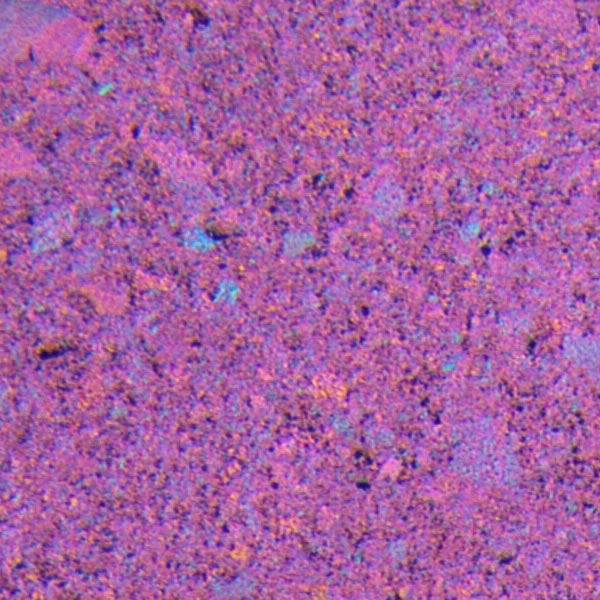

Ultra-High-Density Carbon Products

(Metaphite)Metaphite is an unparalleled ultra-high-density carbon product manufactured by the unique method of melting and sintering a single raw material which is made through unification of aggregates and binders. It is an epoch-making material with bulk density of 2.0 that is nearing the industrial limit.

-

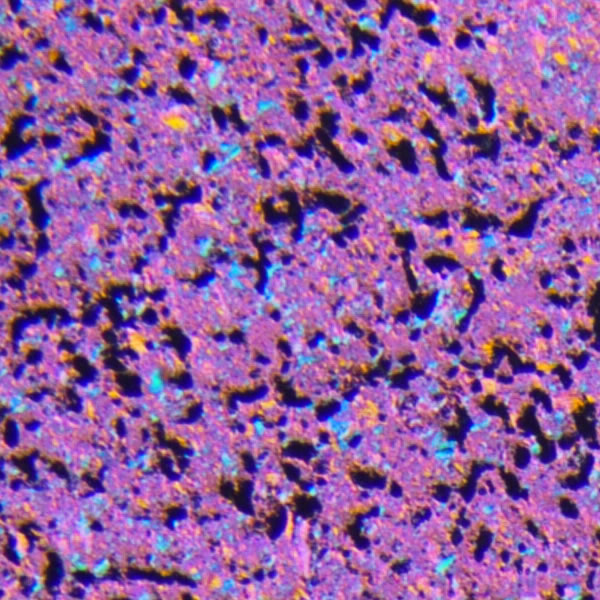

High-Density Carbon Products

(Isostatic Graphite/ Molded Graphite)High-density carbon products are carbon products having a homogeneous fine structure made by using ultra-fine grain aggregate. A variety of products are available depending on their usages, which are made by utilizing choice raw materials and unique processing techniques. In addition to the variety of grades, such sizes as a cylindrical block with a diameter of more than 1m and a very large square block are also available.

-

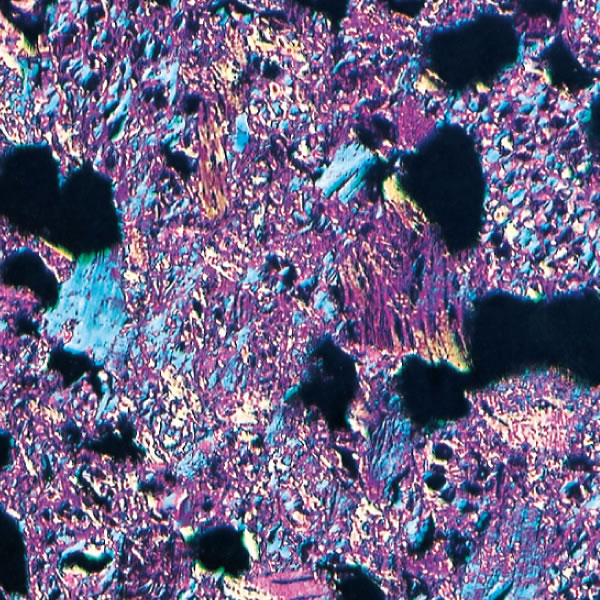

General Purpose Carbon Products

(Extruded Products)General purpose carbon products are carbon products having a big grain size, small thermal expansion coefficient and small specific resistance. These are used in various fields such as metallurgical, electrical, electrochemical and chemical structural components.

- Safety Cautions 《Follow the descriptions below for safe use of graphite materials.》

-

- Be careful of burn injuries and electrical shocks, because graphite materials are good conductors of heat and electricity. Take measures against powder dust in order to prevent leakage and short-circuit troubles due to powder dust or chips of graphite materials.

- In case powder dust or chips of graphite materials get into your eyes, please wash your eyes immediately. If the powder dust or chips cannot be removed, receive medical treatment. If any dust or chip is stuck to your skin, please wash them away by using water with or without soap.

- Graphite materials are slippery. In cases where the graphite materials are stuck on the floor, please sweep the floor to prevent people from falling down.

- Raw materials are as slippery as final products. Your fingers can be jammed in them or they may drop on your foot. To prevent this, wear gloves and safety shoes when handling graphite materials.

- Since graphite materials are brittle, mechanical shocks can break graphite materials triggering fragments of the graphite materials to fly or drop, which may result in injuries to you.

- Wetting by water or oil can decrease the performance of the materials.

- Have an authorized waste-disposal company dispose used products as industrial wastes when you will be disposing them.